K-Profiles¶

Manage pressure advance (K-factor) settings for optimal print quality across different filaments.

What is Pressure Advance?¶

Pressure advance (K-factor) compensates for filament compression in the extruder:

- Too low: Bulging corners, blobs at start

- Too high: Gaps at corners, weak lines

- Just right: Clean corners, consistent extrusion

Different filaments need different K values.

K-Profile Storage¶

Bambuddy stores K-profiles per:

- Printer - Each printer has its own values

- Filament - Different K per material

- Nozzle - Values vary by nozzle size

Retrieving K-Profiles¶

From Printer¶

Pull current K-profiles from your printer:

- Go to K-Profiles page

- Select your printer

- Click Fetch from Printer

- K-values are downloaded

What's Retrieved¶

| Data | Description |

|---|---|

| Material | Filament type |

| K-factor | Pressure advance value |

| Nozzle | Nozzle diameter |

| Notes | Any stored notes |

Pushing K-Profiles¶

To Printer¶

Send K-profiles to your printer:

- Go to K-Profiles page

- Select profiles to push

- Click Push to Printer

- Profiles are uploaded

Overwrites Existing

Pushing profiles overwrites the printer's current K values for that material.

Editing K-Profiles¶

Modify Values¶

- Click on a K-profile

- Edit the K-factor value

- Add optional notes

- Click Save

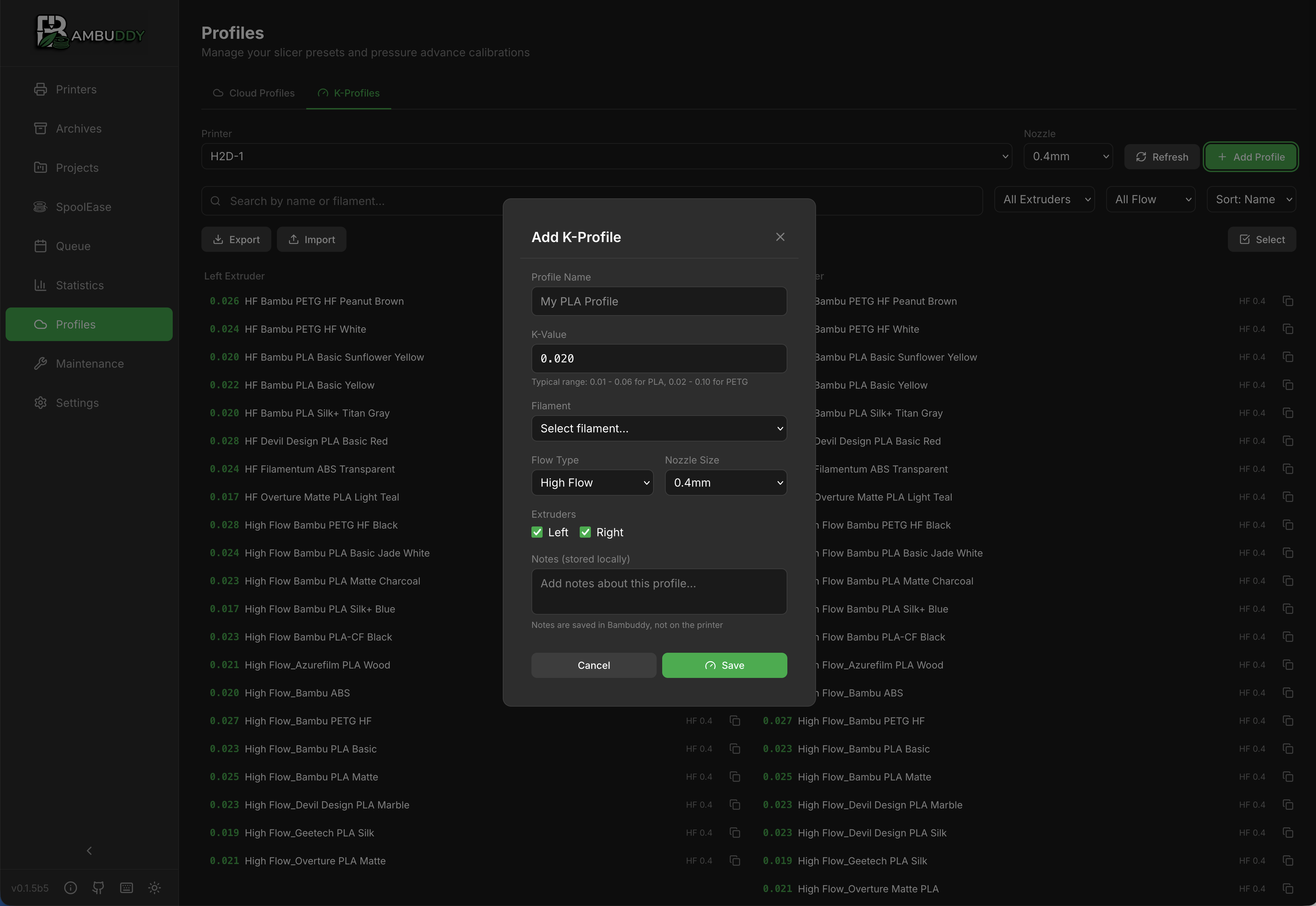

Value Guidelines¶

| Material | Typical K Range |

|---|---|

| PLA | 0.02 - 0.06 |

| PETG | 0.06 - 0.12 |

| ABS/ASA | 0.04 - 0.08 |

| TPU | 0.20 - 0.50 |

These are starting points

Actual values depend on your specific printer, filament brand, and nozzle.

Adding K-Profiles¶

Manual Entry¶

- Click Add K-Profile

- Select material type

- Enter K-factor value

- Select nozzle size

- Add notes if desired

- Click Save

From Calibration¶

After running calibration:

- Note the optimal K value

- Add or update the profile

- Save for future use

Calibration¶

Running K-Factor Calibration¶

Bambu Lab printers include built-in calibration:

- Load the filament to calibrate

- From printer or Bambu Studio, run flow calibration

- Observe the test pattern

- Note the optimal K value

- Update the K-profile in Bambuddy

Third-Party Methods¶

Alternative calibration methods:

- Marlin K-factor test patterns

- Pressure advance tower prints

- Corner flow tests

Copying Profiles¶

Between Printers¶

Copy K-profiles to another printer:

- Select source profiles

- Click Copy to Printer

- Select destination printer

- Profiles are copied

Fine-tune After Copy

Copied values may need adjustment for different hardware.

Sync Status¶

Profile States¶

| Status | Meaning |

|---|---|

| Synced | Matches printer |

| Modified | Local changes not pushed |

| New | Not on printer yet |

Keeping in Sync¶

- Fetch after printer changes

- Push after local edits

- Regular sync recommended

Comparing Values¶

View Differences¶

Compare K-values between:

- Different printers

- Bambuddy vs printer

- Different materials

Backup¶

Exporting K-Profiles¶

- Go to K-Profiles

- Click Export

- Download JSON file

Importing K-Profiles¶

- Click Import

- Select JSON file

- Review and confirm

Useful for backup or transferring to new installations.

Troubleshooting¶

Fetch Failed¶

- Verify printer connection

- Check printer is not busy

- Try again

Push Failed¶

- Check printer is idle

- Verify connection status

- Ensure no active prints

Values Don't Apply¶

- Verify profile was pushed

- Check material matches slicer

- Re-slice if needed

Tips¶

Calibrate Each Filament

Even same material from different brands may need different K values.

Note the Brand

Add brand/color to notes for easy identification.

Regular Updates

Recalibrate after nozzle changes or significant printer maintenance.

Start Conservative

When unsure, start with a lower K value and increase gradually.

Backup Before Changes

Export profiles before making major changes.