Maintenance Tracker¶

Schedule and track maintenance tasks to keep your printers running reliably.

Overview¶

The maintenance tracker helps you:

- Schedule recurring maintenance tasks

- Track when maintenance was last performed

- Get notified when maintenance is due

- Log maintenance history

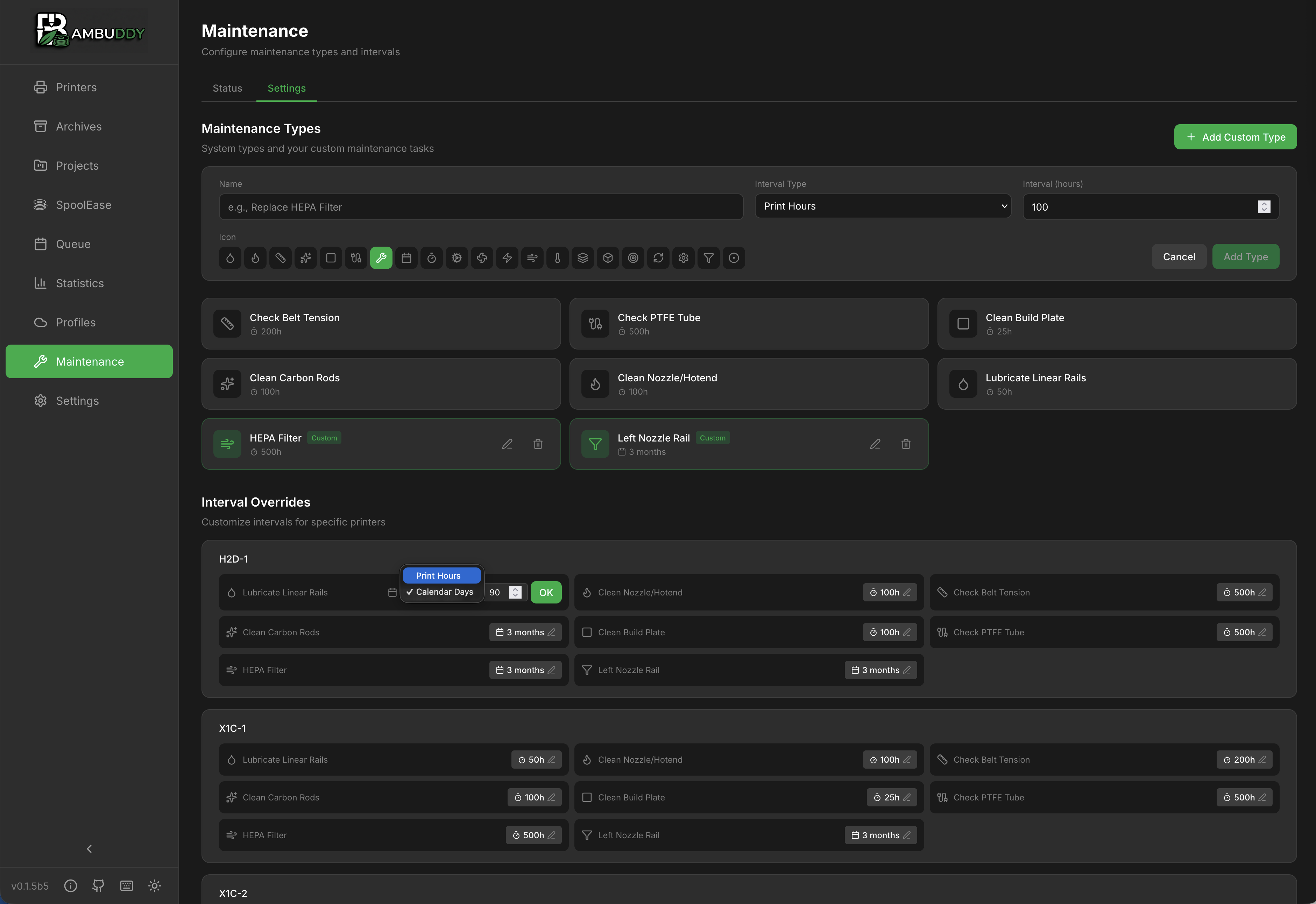

Maintenance Types¶

Default Types¶

Bambuddy includes common maintenance tasks:

| Type | Default Interval |

|---|---|

| Bed Cleaning | Every 10 prints |

| Lubrication | Every 100 hours |

| Belt Tension | Every 200 hours |

| Nozzle Check | Every 50 prints |

| HEPA Filter | Every 500 hours |

| Carbon Filter | Every 500 hours |

Hiding Default Types¶

If a default maintenance type isn't relevant to your setup, you can remove it:

- Go to Settings > Maintenance

- Click the icon next to the default type

- Confirm deletion

Hidden default types can be restored at any time — click Restore Default Tasks to bring them all back.

Custom Types¶

Create your own maintenance tasks:

- Go to Settings > Maintenance

- Click Add Maintenance Type

- Enter name and description

- Set default interval

- Click Save

Interval Types¶

Print Count¶

Schedule based on number of prints:

- Example: Clean bed every 10 prints

- Resets after maintenance is logged

Print Hours¶

Schedule based on actual print time:

- Example: Lubricate every 100 hours

- Accumulated from print durations

Calendar Days¶

Schedule based on calendar time:

- Example: Check belts every 30 days

- Counts calendar days regardless of usage

Setting Up Maintenance¶

Per-Printer Configuration¶

Each printer has its own maintenance schedule:

- Go to Maintenance page

- Select your printer

- Click Configure

- Enable/disable maintenance types

- Adjust intervals as needed

- Click Save

Interval Customization¶

Override default intervals per printer:

| Printer | Bed Cleaning |

|---|---|

| Workshop X1C | Every 10 prints |

| Office P1S | Every 5 prints |

| Garage A1 | Every 20 prints |

Logging Maintenance¶

Marking Complete¶

When you perform maintenance:

- Go to Maintenance page

- Find the due/overdue item

- Click Mark Complete

- Optionally add notes

- Counter resets

Logging Details¶

Add information to maintenance logs:

| Field | Description |

|---|---|

| Date | When performed |

| Notes | What you did |

| Parts | Any parts replaced |

Due Status¶

Status Indicators¶

| Status | Meaning |

|---|---|

| OK | Not due yet |

| Due Soon | Approaching due |

| Overdue | Past due |

Due Soon Threshold¶

Configure when "Due Soon" triggers:

- Default: 80% of interval

- Example: Bed cleaning every 10 prints → "Due Soon" at 8 prints

Notifications¶

Get notified when maintenance is due:

- Go to Settings > Notifications

- Enable Maintenance Due event

- Configure your notification provider

Notification Timing¶

- Due Soon: When threshold reached

- Overdue: When interval exceeded

Maintenance History¶

View past maintenance for each printer:

History Log¶

| Date | Type | Notes |

|---|---|---|

| Dec 14 | Bed Cleaning | IPA wipe |

| Dec 10 | Lubrication | Rails and screws |

| Dec 1 | Nozzle Check | Replaced with 0.4mm |

Exporting History¶

Export maintenance logs for records:

- CSV format

- Date range selection

- Per-printer or all printers

Per-Printer View¶

Dashboard¶

Each printer shows maintenance status:

Workshop X1C

─────────────────────────────

✅ Bed Cleaning 2 prints until due

⚠️ Lubrication 8 hours until due

❌ Belt Tension OVERDUE

✅ Nozzle Check 45 prints until due

Quick Actions¶

- View Details: See full maintenance info

- Mark Complete: Log completed maintenance

- View History: See past maintenance

Maintenance Tips¶

Bed Cleaning

Clean with IPA between prints for best adhesion. Deep clean with dish soap weekly.

Lubrication

Use appropriate grease for linear rails. Don't over-lubricate.

Belt Tension

Belts should be firm but not overly tight. Use the "guitar string" test.

Nozzle Inspection

Check for wear, especially with abrasive filaments. Replace when worn.

Filters

HEPA and carbon filters lose effectiveness over time. Replace as recommended.

Document Everything

Add notes when logging maintenance to build a history of what works.

Best Practices¶

Regular Schedule¶

- Check maintenance status weekly

- Don't skip overdue items

- Build maintenance into your routine

Preventive vs Reactive¶

- Preventive: Follow intervals

- Reactive: Fix when broken

- Preventive is better!

Track Everything¶

- Log all maintenance

- Note any issues found

- Track parts replaced