Print Queue¶

Queue and schedule prints with drag-and-drop ordering, timed starts, and smart plug automation.

Queue Overview¶

The print queue lets you:

- Queue prints from your archive

- Order with drag-and-drop

- Schedule specific start times

- Automate with smart plug integration

- Track queue progress

SD Card Required

An SD card must be inserted in your printer for the print queue to work. Files are transferred to the printer's SD card when prints start.

Adding to Queue¶

From Archive¶

- Go to Archives page

- Click the Schedule button on the archive card (or right-click and select Schedule)

- Choose target printer

- Optionally configure filament mapping (see below)

- Print is added to queue

Quick Access

The Schedule button appears directly on archive cards next to Reprint for sliced files, making it easy to queue prints without using the context menu.

From File Manager¶

- Go to File Manager page

- Select sliced files (

.gcodeor.gcode.3mf) - Click Add to Queue in toolbar (or right-click context menu)

- Choose target printer (or leave unassigned)

- Files are archived and queued automatically

From Queue Page¶

- Go to Queue page

- Click Add Print

- Browse and select an archive

- Choose target printer

- Optionally set schedule time

- Optionally configure filament mapping

AMS Filament Mapping¶

When adding multi-color prints to the queue, you can configure which AMS slot to use for each filament:

- Expand the Filament Mapping section

- View auto-matched filaments (type + color)

- Click any dropdown to manually select a different AMS slot

- Color names shown for easy identification (decoded from Bambu filament codes)

- Mapping is stored with the queued print

Dual-Nozzle Printers (H2D/H2D Pro):

On dual-nozzle printers, filament matching is nozzle-aware. Each filament requirement shows an L or R badge indicating which nozzle it targets. Auto-matching only considers AMS trays connected to the correct nozzle via ams_extruder_map. This prevents sending filament meant for the left nozzle to the right one and vice versa.

Stored Mappings

AMS mappings are saved when you add a print to the queue. When the print starts, Bambuddy uses your configured mapping instead of auto-matching again.

Plate Selection (Multi-Plate 3MF)¶

For 3MF files with multiple plates:

- Click Edit on a queued item

- Scroll to Plate Selection section

- Browse plates with thumbnails and print times

- Click to select the plate to print

- Filament requirements update to show selected plate's filaments

Single Plate per Queue Item

Each queue item prints one plate. To print multiple plates from the same file, add the file to queue multiple times and select different plates.

Print Options¶

Configure printer settings for each queued print:

- Click Edit on a queued item

- Expand Print Options section

- Toggle options as needed:

| Option | Description |

|---|---|

| Bed Levelling | Auto-level bed before print |

| Flow Calibration | Calibrate flow before print |

| Vibration Calibration | Reduce vibration artifacts |

| Layer Inspect | Enable AI first layer inspection |

| Timelapse | Record timelapse video |

| Use AMS | Use AMS system for filament |

Default Settings

Default values match typical printing needs. Adjust only if your print requires specific settings.

Drag and Drop Ordering¶

Reorder prints in the queue:

- Hover over a queued print

- Grab the drag handle

- Drag to new position

- Release to reorder

Prints execute in order from top to bottom.

Scheduling¶

Immediate Prints¶

Add to queue without a schedule - prints start when:

- Printer is idle

- Previous prints complete

- No scheduled prints are pending

Scheduled Prints¶

Set a specific start time:

- Click Schedule on queued print

- Choose date and time

- Print starts at scheduled time

Schedule Priority¶

Scheduled prints take priority:

- Check for scheduled prints at scheduled time

- If none, check immediate queue

- Start next print

Queue Only (Staged Prints)¶

Stage prints without automatic scheduling:

- When adding to queue, select Queue Only

- Print shows with purple Staged badge

- Print won't start automatically

- Click Play button to release to queue

Use Queue Only to:

- Prepare print batches before activating

- Stage prints across multiple printers

- Review and approve before printing starts

- Build a queue without immediate execution

Batch Workflow

Add multiple prints with Queue Only, review the order, then release them one by one or all at once.

Smart Plug Automation¶

Combine with smart plugs for full automation:

Auto Power On¶

When a queued print is ready:

- Bambuddy checks if printer is on

- If off and smart plug configured, powers on

- Waits for printer to boot

- Starts the print

Auto Power Off¶

After print completes:

- Print completes

- Cooldown period (configurable)

- Check if more prints queued

- If no more prints, power off

Configuration¶

- Go to Settings > Smart Plugs

- Configure plug for printer

- Enable Auto Power On and Auto Power Off

- Set cooldown temperature and time

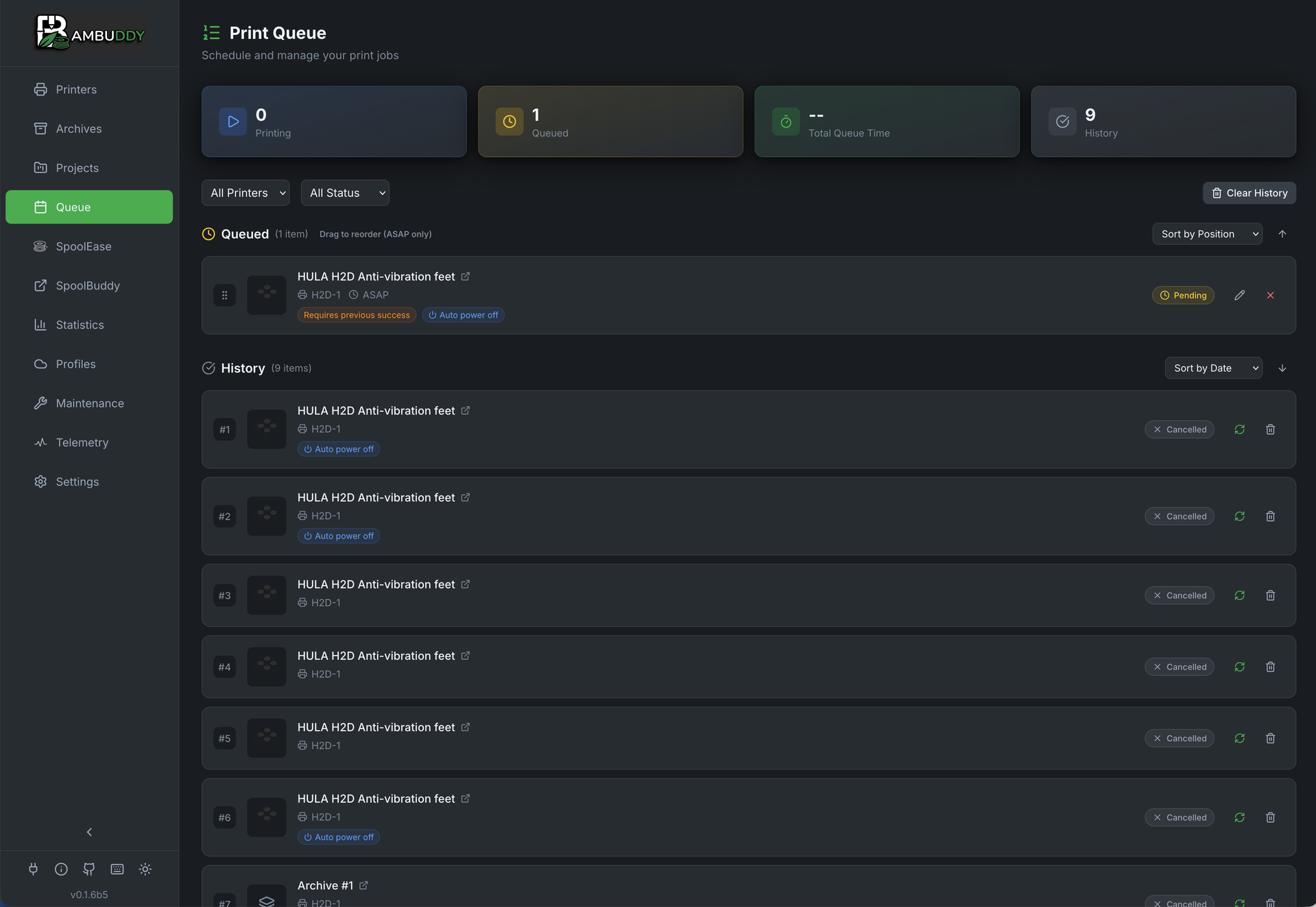

Queue Status¶

Print States¶

| State | Icon | Description |

|---|---|---|

| Queued | Waiting in queue | |

| Scheduled | Waiting for scheduled time | |

| Starting | Sending to printer | |

| Printing | Currently printing | |

| Completed | Successfully finished | |

| Failed | Print failed | |

| Cancelled | Manually removed |

Queue Card¶

Each queued print shows:

- Thumbnail (shows the selected plate's thumbnail for multi-plate files)

- Print name

- Target printer

- Estimated duration

- Scheduled time (if set)

- Status

- Added by (username who queued the print, when authentication is enabled)

Managing Queue¶

Remove from Queue¶

- Click the X on any queued print

- Confirm removal

- Print is removed (not deleted from archive)

Cancel Running Print¶

- Find the currently printing item

- Click Cancel

- Print stops on printer

- Marked as cancelled in queue

Clear Plate Confirmation¶

When a print finishes or fails and more items are queued for the same printer, the next print does not start automatically. Instead, the printer card shows a "Clear Plate & Start Next" button.

- Remove the finished print from the build plate

- Click Clear Plate & Start Next on the printer card

- The scheduler starts the next queued print within 30 seconds

This prevents prints from starting on a dirty plate. The button appears whenever the printer is in Finished or Failed state with pending queue items.

Permission Required

The Clear Plate button requires the Printers Control permission when authentication is enabled.

Clear Queue¶

Remove all queued prints:

- Click Clear Queue button

- Confirm action

- All pending prints removed

Running Print Not Affected

Clear Queue only removes pending prints, not the currently active print.

Bulk Editing¶

Edit multiple queued items at once:

Selecting Items¶

- Look for checkboxes on pending queue items

- Click checkbox to select/deselect individual items

- Use Select All / Deselect All in the toolbar

Bulk Edit Modal¶

When items are selected, click Edit Selected to open the bulk edit modal:

| Setting | Description |

|---|---|

| Printer | Reassign all selected items to a different printer |

| Staged | Toggle manual start (Queue Only) mode |

| Auto power off | Toggle auto power off after print |

| Require previous success | Toggle conditional execution |

| Bed levelling | Toggle bed levelling |

| Flow calibration | Toggle flow calibration |

| Vibration calibration | Toggle vibration calibration |

| First layer inspection | Toggle AI inspection |

| Timelapse | Toggle timelapse recording |

| Use AMS | Toggle AMS usage |

Tri-State Toggles¶

Each setting has three states:

| State | Symbol | Meaning |

|---|---|---|

| Unchanged | — | Don't modify this setting |

| Off | Off | Set to disabled on all selected items |

| On | On | Set to enabled on all selected items |

Only settings you explicitly change are applied - other settings remain as they were.

Bulk Cancel¶

Click Cancel Selected to cancel all selected pending items at once.

Quick Reassignment

Use bulk edit to quickly reassign multiple prints to a different printer when one becomes unavailable.

Multi-Printer Queue¶

Queue prints across multiple printers:

Per-Printer Queues¶

Each printer has its own queue:

- Filter by printer to see specific queue

- Prints wait for their assigned printer

- Different printers can print simultaneously

Multi-Printer Selection¶

Send the same print to multiple printers at once:

- Open Add to Queue or Re-print modal

- Select multiple printers using checkboxes

- Use Select all / Clear buttons for quick selection

- Configure filament mapping (default applies to all printers, or use per-printer mapping)

- Click submit to send to all printers

Print Farms

Multi-printer selection is ideal for print farms. Use the default mapping for printers with identical filament configurations, or enable per-printer mapping for mixed setups.

Per-Printer AMS Mapping¶

When multiple printers are selected, you can configure filament slot mapping individually for each printer:

- Select multiple printers

- Under each printer, check Custom mapping to enable per-printer configuration

- The mapping section expands showing:

- Required filaments with color indicators

- Dropdown to select AMS slot for each requirement

- Match status: exact, type-only, missing

- Click Auto to auto-configure using RFID data

- Click Re-read to refresh the printer's loaded filaments

| Control | Description |

|---|---|

| Custom mapping checkbox | Enable per-printer slot configuration |

| Auto button | Auto-match filaments using RFID data |

| Re-read button | Refresh loaded filaments from printer |

| Match indicator | Shows (X/Y matched) status |

Default Expanded

Go to Settings → Filament and enable Expand custom mapping by default to automatically expand per-printer mapping for all printers when multi-selecting.

Auto-Configure

The Auto button reads RFID data from loaded spools and matches them to required filaments by type and color. It prioritizes exact matches, then similar colors, then type-only matches.

Choosing a Printer¶

When adding to queue:

- Select one or more target printers

- Prints join each printer's queue

- Different archives can go to different printers

Load Balancing¶

Manually distribute prints:

- Add long prints to less-used printers

- Queue time-sensitive prints on fastest printer

- Keep specific materials on specific printers

- Use multi-printer selection for batch production

Model-Based Queue Assignment¶

Queue prints to "any printer of matching model" for automatic load balancing across identical printers.

How It Works¶

- When you add a print to the queue, select Any [Model] instead of a specific printer

- Optionally select a Location to further filter available printers (e.g., "Any X1C in Workshop")

- Bambuddy extracts the printer model from the sliced 3MF file (e.g., "X1C", "P1S")

- The scheduler automatically assigns the print to the first idle printer of that model (and location, if specified)

- If filament validation is enabled, it only assigns to printers with the required filaments loaded

Adding Model-Based Queue Items¶

- Open Add to Queue modal

- In the printer selection, choose Any X1C, Any P1S, etc.

- Optionally select a Location from the dropdown to filter by printer location

- Configure other options as usual

- Submit - the print joins the queue without a specific printer

Location Filtering¶

When you have multiple printers of the same model in different locations:

- Choose Any [Model] for the printer

- Select a Location from the dropdown (shows all locations from your printers)

- The scheduler only considers printers at that location

- Queue items show the target location (e.g., "Any X1C - Workshop")

Filtering Queue by Location

On the Queue page, use the Location dropdown filter to view only jobs for a specific location.

Filament Validation¶

When a model-based queue item has required filaments:

- Scheduler checks each printer of the matching model

- Only printers with all required filament types loaded (in AMS or external spool) are considered

- Jobs wait until a compatible printer becomes available

- The Waiting status (purple badge) shows why a job is waiting

Waiting Status¶

Model-based queue items show detailed status:

| Status | Description |

|---|---|

| Pending | Ready to start, waiting for idle printer |

| Waiting | Blocked - shows reason (e.g., "Waiting for filament: Printer1 (needs PLA)") |

| Printing | Assigned to printer and running |

The waiting reason tells you exactly what's needed:

- Waiting for filament: Which printers are missing which filament types

- Busy: Which printers are currently printing

- Offline: Which printers are disconnected

Compatibility Warnings¶

When queuing to a specific printer that doesn't match the sliced model:

- A warning shows "File was sliced for X1C, but printing on P1S"

- This helps avoid issues from mismatched print profiles

Print Farm Load Balancing

Model-based assignment is ideal for print farms with multiple identical printers. Queue prints to "Any X1C" and let Bambuddy distribute work automatically.

Queue Notifications¶

Get notified about queue events. Configure these in Settings → Notifications under "Print Queue":

| Event | Default | Description |

|---|---|---|

| Job Added | Off | Job added to queue |

| Job Assigned | Off | Model-based job assigned to a printer |

| Job Started | Off | Queue job started printing |

| Job Waiting | On | Job waiting for filament (actionable) |

| Job Skipped | On | Job skipped due to previous print failure |

| Job Failed | On | Job failed to start (upload error, etc.) |

| Queue Complete | Off | All queued jobs finished |

Actionable Notifications

The most important notifications (Waiting, Skipped, Failed) are enabled by default because they require user action. Enable others based on your monitoring needs.

Queue History¶

View past queue activity:

- Completed prints

- Failed prints

- Cancelled prints

- Execution times

History helps you:

- Track throughput

- Identify patterns

- Debug issues

API Access¶

Manage queue programmatically:

# Add to queue

POST /api/v1/queue

# Get queue status

GET /api/v1/queue

# Remove from queue

DELETE /api/v1/queue/{id}

See API Reference for details.

Tips¶

Overnight Prints

Schedule longer prints to start overnight - wake up to finished prints!

Smart Plug Combo

Combine scheduling with auto power-off for hands-free operation.

Queue Batch Jobs

Queue multiple small prints for efficient batch production.

Priority Management

Move urgent prints to the top of the queue with drag-and-drop.

Estimated Times

Check estimated durations when scheduling to avoid printer conflicts.